High-Tech Horizontal Structural Bundle Automatic Indexing Band Saw -

HF-700PRO

Views

HF-700PRO

Contact- Specifications

- Configuration Table

| Specifications | |||

| HF-700PRO | |||

Cutting range | Cutting range round | Ø660mm | Ø26in |

Cutting range square (W x H) | 700*660mm | 27.5*26in | |

Smallest size to be cut | 30*30mm | 1.2*1.2in | |

Clamping range | 20-700mm | 0.8-27.5in | |

Bundle cutting range (Min.W x H - Max. W x H ) | 30*30-700*660mm | 1.2*1.2-27.5*26in | |

Shortest length of cut-off piece | 20mm | 0.8in | |

Shortest remnant length in automatic operation, possible only if the material has a perfect geometric surface | 400mm | 16in | |

Shortest remnant length individual cut | 20mm | 0.8in | |

| Dimensions and weight | Length | 3150mm | 124in |

| Width incl. chip conveyor | 4300mm | 170in | |

| Height | 3080mm | 121.3in | |

| Material support height | 895mm | 35.2in | |

Total weight | ≈6400kg | ≈14109lb | |

| Performance characteristics | Total connected load | 17.8kw | 23.7hp |

Power of saw motor | 11kw | 14.66hp | |

Hydraulic motor | 2.2kw | 1hp | |

Cutting speed infinitely variable with | 20-90m/min | 65.6-295.2ft/min | |

Saw feed speed | 1-300 mm/min | 0.04-11.8in/min | |

Automatic material feed length, single stroke | 1000mm | 39.4in | |

Automatic material feed length, multiple stroke | 9999mm | 393.66in | |

Dimensions of saw blade | 8100*54*1.6mm | 318.9*2.1*0.06in | |

| Configuration Table | ||

| Category of configuration | Functional description | HF-700PRO |

| Exterior Protection | CE safety protection | ● |

| Downfeed System | JLH-EHA | ● |

| Saw Master | ● | |

| ELECTRICS | CE Electrical Safety | ● |

UL Electrical Safety | ○ | |

Permanent Magnetic synch. Motor | ● | |

Sawbow anti-collision detection | ● | |

LED working light | ● | |

Laser line projection | ○ | |

Blade breakage detection | ● | |

Sawing Depth Control | ● | |

| HMI+Buttons | ● | |

| Inverter | ● | |

| Deviation detector | ● | |

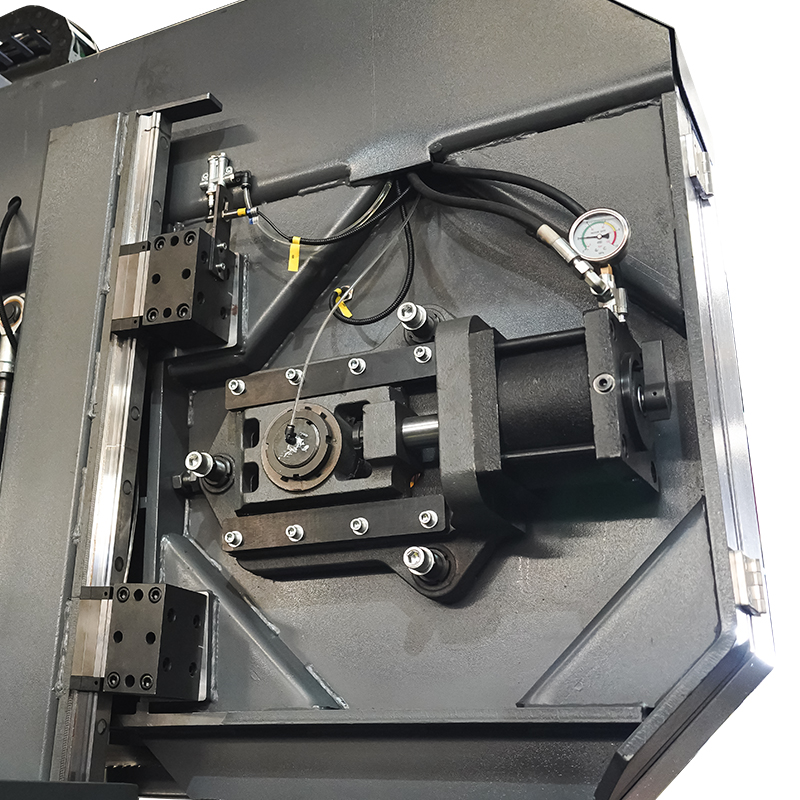

| HYRAULICS | Hydraulic Blade tension | ● |

| Vise pressure differential valves | ○ | |

| Automatic chip conveyor (spiral) | ● | |

| Hydraulic blade guide clamping | ● | |

| Vise pressure regulator | ● | |

| Motorized chip brush | ● | |

| Top clamp | ● | |

| Hydraulic cooling fan | ● | |

| Auto Lubrication device | ● | |

| Roller type work table | ● | |

| MATERIAL FEEDING | Hydraulic driven | ● |

| Servo driven | ○ | |

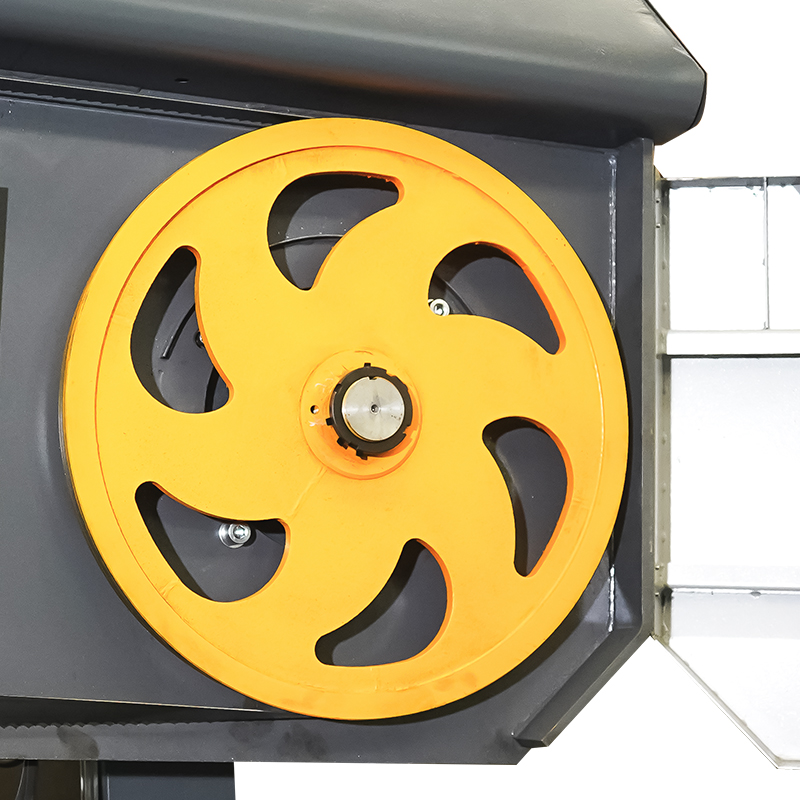

| Mechanical structure | Main drive precision gear reducer | ● |

| Split Vise clamping | ● | |

| Hydraulic movable Guide arm | ● | |

| Other | Chip collection box (movable) 70 (L) | ● |

| Tool box (wire brush, levelling pads, spare paint) | ● | |

| One piece Saw blade | ● | |

| Transport underframe for containers | ○ | |

| ● : Standard ○ : Optional × : Non-optional | ||